Description

Application:

Automated production of hamburger patties

Features:

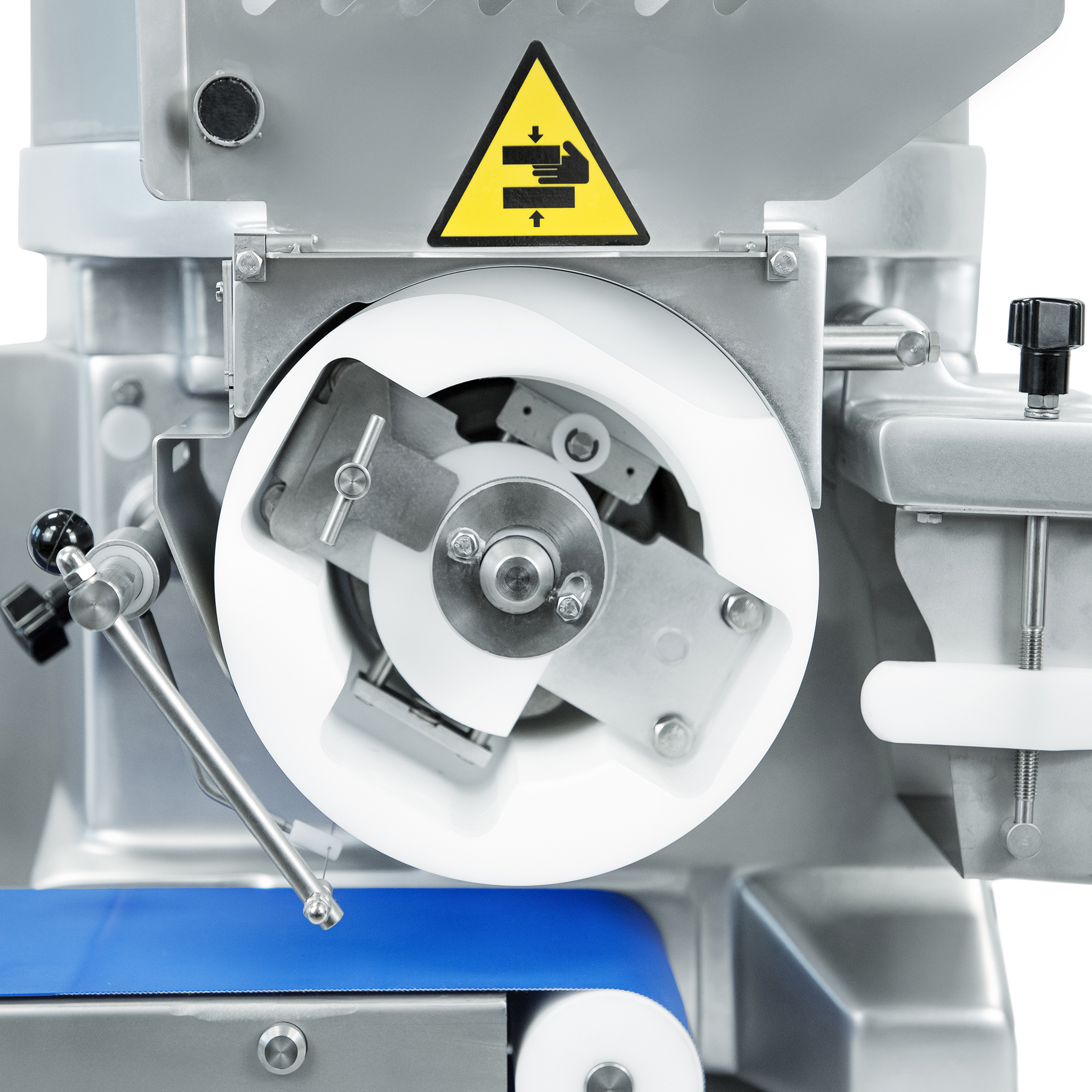

- Easy adjustment of patty height using a regulating and locking screw in the moulding drum

- Optimal results thanks to rotating mixing paddle for constant and even mixing of the mass to be processed

- Cast parts made of Peraluman, other individual parts made of stainless steel

- Depending on use, with single, double or special moulding drum

- In combination with the BF ball former, only with double moulding drum

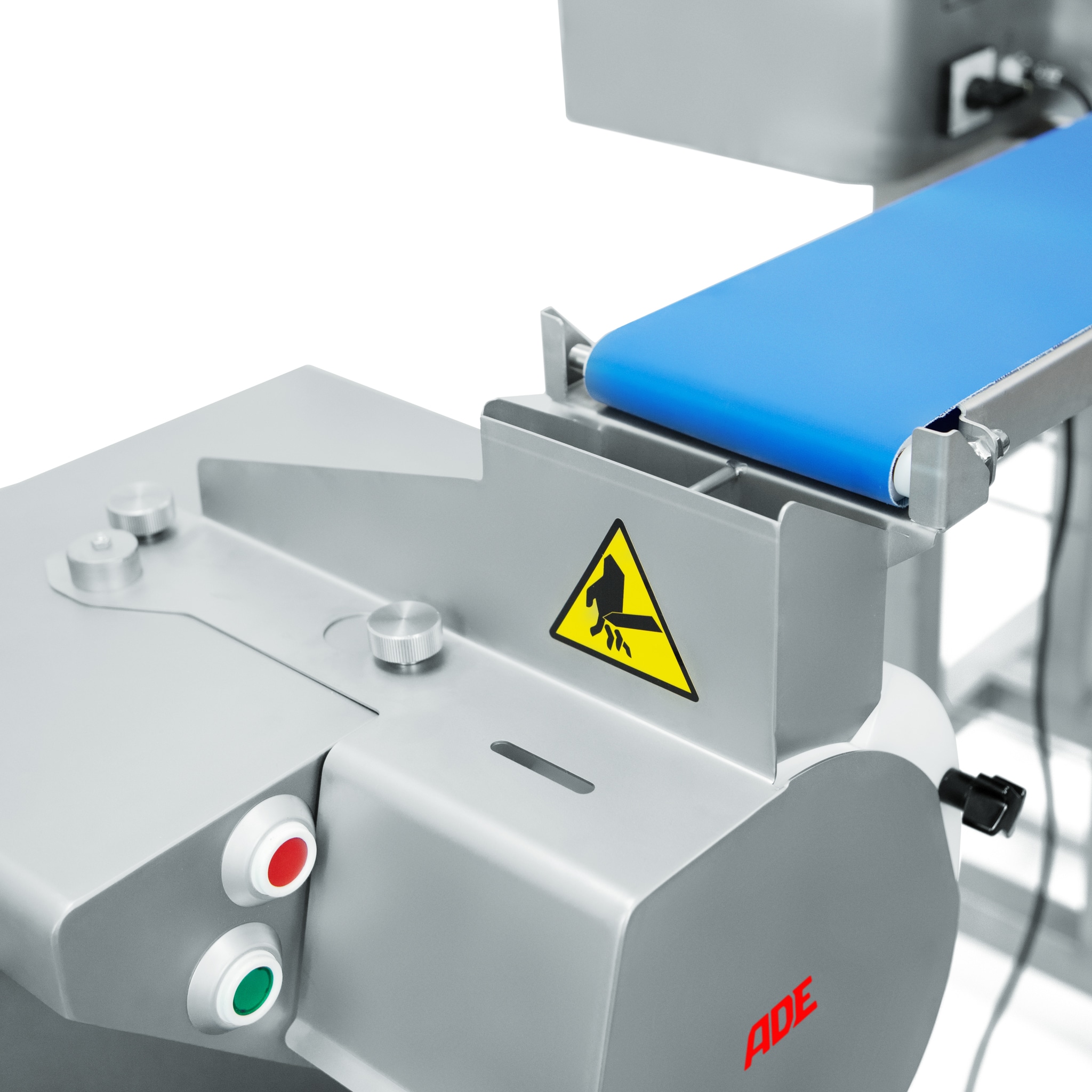

- Standard with 900 mm conveyor belt length, 20 litre filling hopper, stainless steel mixing paddle, manual scraper on the moulding drum, pedal for foot control, mobile base frame for Bully2000 and ball former BF with water distribution system with height-adjustable and mobile base frame

- Easy disassembly of mixing paddle, hopper, scraper, conveyor belt, moulding drum and accessories for easy cleaning

- Easy cleaning of the housing with a water hose (no high pressure!)